Egg products

The term "egg products" refers to eggs that have been removed from their shell for processing. Processing of egg products includes breaking, filtering, mixing, stabilizing, melting, pasteurizing, cooling, freezing or drying, and packaging. This is done at USDA inspected plants. Egg products include whole eggs, whites, yolks, and some of the mixtures with or without egg ingredients that are processed and pasteurized and may be available in liquid, frozen, and powdered forms.

Eggs for consumption, their products and derivatives are classified as follows:

1. Shell Eggs:

-

Table Eggs.

2. Powder Egg:

-

Dehydrated egg.

-

Dehydrated Egg Yolk.

-

Dehydrated Egg White.

3. Liquid and/or Frozen Egg:

-

Refrigerated or Frozen Liquid Egg.

-

Refrigerated or Frozen Liquid Egg Yolk.

-

Refrigerated or Frozen Liquid Egg White.

There are other forms, such as:

Frozen: Scrambled egg mix, salted whole egg or yolks, sugar yolks, whole eggs with corn syrup, whole eggs with citric acid, unsweetened or unsalted egg whites, etc.

Egg Product Specialties: Cooked eggs, peeled and diced, cooked eggs, peeled and unpeeled, plain or pickled, whole, sliced or cubed, etc.

If you wish to know more information provided by FSIS about egg products, you may click on the following link:

a) Agencies, Organizations and Programs

Below are the Government Agencies and private organizations regulating, verifying and providing information regarding goods subject matter herein, and their main activities are also listed. Also, the laws, programs and associations applicable to the goods are shown in order to know and clarify the actions and paperwork that are to be carried out by exporters in order to send their products into Mexico.

AMS (Agricultural Marketing Service)

-

It is in charge of the Shell Eggs Surveillance Program which ensures that eggs sold in the marketplace meet equal or better standards than Grade B.

-

It performs annual inspections in the production farms or hatcheries, and in places where eggs are handled, to ensure they meet the requirements.

-

It manages a voluntary program used in classification by quality grades of eggs for shell eggs. This is paid for by the processing plants.

-

Since April 1998, it prohibits repackaging of eggs previously sent for retail, and packaged under the voluntary grading classification program.

-

It issues the export certificate for processed eggs.

-

(PEEPEV) Processed egg products according to the Processed Egg and Egg Products Export Verification Program.

The Letterhead Certificate is available in the following link:

https://www.fsis.usda.gov/sites/default/files/media_file/2021-02/mexico-egg-products-lhc.pdf

FSIS (Food Safety Inspection Service) USDA’s Agency

-

It ensures processed eggs or its components have been inspected, passed by FSIS and meet all the additional requirements of the importing country.

-

It regulates dehydrated, frozen or liquid egg products.

-

It is the competent authority for exportation of processed egg products and their certification for their exportation.

-

It maintains integrity, safety and accuracy in all certification processes for exports.

-

It regulates all processing egg-product plants (plants cracking and pasteurizing eggs).

-

It is accountable for all imported eggs for further processing, and to ensure imported shell eggs for retail stores are transported under refrigeration.

-

It verifies shell eggs packaged for consumers are labeled with legends, such as: “Keep Refrigerated”, and transported under refrigeration and at ambient temperature not greater than 45 ºF (7.22 ºC). https://www.fsis.usda.gov/food-safety/safe-food-handling-and-preparation/eggs/shell-eggs-farm-table

-

Exporters interested in sending their goods to Mexico shall fill out and submit form FSIS 9060-6 (Application for Export Certificate). With this application, FSIS will issue a sanitary Certificate for exportation of egg products. Form FSIS 9060-6 is a formality carried out in the US and is prior to the issuance of the sanitary Export Certificate, that is to say, it is a necessary requirement only before the US Sanitary Authority and, not for Mexico.

-

Form FSIS 9060-5EP is issued by FSIS operations personnel. This document is submitted to the Mexican health authority, and it certifies that egg products specified therein have been inspected and passed in accordance to the applicable USDA regulations, and are wholesome, and fit for human consumption. The document is issued for the exporter, and it includes the following:

-

General consignee’s information. Other pieces of information included in the form are:

-

District Office,

-

Country of Destination,

-

Serial Number,

-

Establishment Number and City,

-

Type of Facility,

-

Total Marked Net Weight, Total Container Number,

-

Labeled Products with their Individual Weight, Number of Packages and Plant Number Marks,

-

Additional Certification Statements, as required by SENASICA’s Animal Health Requirements Sheet.

-

If you wish to know form FSIS 9060-5EP, and see how to correctly fill it out, you may click on the following link:

https://www.fsis.usda.gov/sites/default/files/2021-07/Sample-9060-5EP-instructions.pdf

Any questions related to export certification for egg products regulated by FSIS can be sent to the importations/exportations coordination and policy development personnel at:

importexport@fsis.usda.gov or calling 202-720-0082 or 1-855-444-9904.

If you want to learn about form FSIS 9060-6 and view instructions on filling it out correctly, you may click on the following link link:

Exporters who need to get a replacement certificate must call FSIS at: 1-855-444-9904, or by email: importexport@fsis.usda.gov.

(FSIS and FDA Cooperation)

-

FSIS and FDA share authority on egg safety and work together to solve the issue of Salmonella in eggs.

FDA (Food and Drug Administration)

-

It verifies that the Egg Safety Rule is complied with.

-

It regulates processed eggs and processed egg products (PEEPEV Program).

-

Production farms shall be authorized by the FDA and are obliged to keep written guidelines summarizing their safety practices.

-

State and local Health Departments, in cooperation with the FDA, supervise the safe handling and good manufacturing practices for table eggs.

-

It regulates egg processing plants, such as: plants where eggs are washed, graded and packaged.

-

It is responsible for products not included in USDA’s definition of “egg products”, as well as the establishments not covered by USDA –for example: restaurants, bakeries and cake mix plants.

NASS (National Service of Agricultural Statistics)

-

It collects information on processing and distribution for industry economic analysis of egg products.

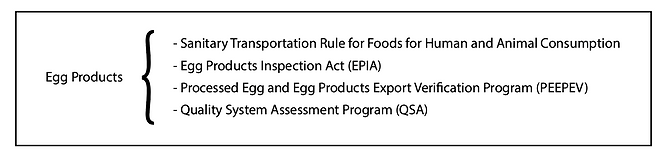

Goods and Agencies Involve

Programs and laws that apply for egg products

b) Rules, laws and regulations to consider

Egg Products Inspection Regulations Final Rule

The Egg Products Inspection Regulations final rule aligns the egg products regulations to be consistent with current requirements in the meat and poultry products inspection regulations. Under the new rule, federally inspected egg products plants are required to develop and implement Hazard Analysis and Critical Control Points (HACCP) systems and Sanitation Standard Operating Procedures (SSOPs). Under the HACCP system, plants will be able to adapt a food safety system that best fits their particular facility and equipment. Changes in the final rule will take place gradually until 2023.

If you would like to know the final rule for egg products, you may click on the following link:

https://www.fsis.usda.gov/shared/audio/032221-AEB-USAPEEC-Egg-Products-Industry-Presentation.pdf

Sanitary Transportation Rule for Foods for Human and Animal Consumption

The objective of this Rule is to prevent practices during transportation that may cause food safety risks, for example. lack of appropriate refrigeration, inappropriate cleaning of vehicles between loads and lack of appropriate food protection.

Specifically, the Rule sets forth the following guidelines:

-

Vehicles and Transportation Equipment: Design and maintenance of vehicles and transportation equipment shall guarantee that they will not cause food transported to become unsafe. For example, they need to be appropriately and adequately “cleanable” for the intended use, and they shall keep the necessary temperature for safe transportation of foods.

-

Transportation Operations: Measures taken during transportation shall guarantee food safety, such as: appropriate temperature controls; prevention of contamination of ready-to-eat products due to contact with raw foods; prevention of contamination due to contact with non-food elements in the same load, or in a previous load; and protection of foods against cross-contamination, for example. involuntary introduction of food allergens.

-

Training: Transportation staff training on sanitary transportation practices and documentation. This training is required when the carrier and the forwarder agree that the carrier is responsible for the sanitary conditions during transportation.

-

Records: Keeping written records on procedures, agreements and training (requirement for the carriers). Retention time required for these records depends on the type of record and when the activity took place, but not to exceed 12 months.

-

It is based on best transportation practices to ensure safety of food products.

If you would like to know the rule specifications for eggs, you may click on the following link: https://www.federalregister.gov/documents/2016/04/06/2016-07330/sanitary-transportation-of-human-and-animal-food

If you would like to know an information sheet on the rule for eggs in Spanish, you may click on the following link: https://www.fda.gov/media/97958/download

Egg Products Inspection Act. (EPIA)

The EPIA provides a continuous mandatory inspection during the process of liquid, frozen or powdered eggs. The Agricultural Marketing Service inspects egg products to ensure that egg products are healthy (unadulterated), properly labeled and packaged to protect the health and well-being of consumers. FSIS inspects all egg products, with the exception of those exempted in the Decree that are used by food manufacturers, in culinary services, institutions, and retail stores.

The measures taken in this decree are appropriate to effectively regulate and protect the health and well-being of consumers.

Points and activities regulated or inspected by the FDA:

-

Inspection of food manufacturing establishments using eggs, institutions and restaurants.

-

Rules and regulations on the operations of egg processing and establishments.

-

Retention, separation and reinspection of eggs and egg products.

-

Applicable measures to adulterated products, such as: destruction and reprocessing.

-

Inspection of commercial sites, facilities, inventory, operations and records of egg handlers.

-

Refrigeration and labeling requirements.

-

Inspections of egg-product processing plants.

-

It ensures that only eggs fit for human consumption are used to this end.

-

Pasteurization and labeling of egg products in plants.

If you wish to know more about the Egg Products Inspection Act, you may follow the following link: https://www.fsis.usda.gov/news-events/news-press-releases/usda-modernizes-egg-products-inspection

Processed Egg and Egg Products Export Verification Program (PEEPEV)

The PEEPEV Program is a voluntary export verification program that helps US food products manufacturers to export processed food products containing eggs to other Countries. Program services are provided by USDA and AMS.

It verifies that processed egg products and cooked eggs are wholesome and fit for exportation.

All program requirements are generic ones, and are aimed at being applicable to all clients, regardless of the company type, size and product. Any requirement in this program that cannot be applied due to the characteristics of the client and its products, shall be considered as not fit or excluded from the program.

The scope of the program includes verification (every 6 months) of the product:

1. That the product for export is certified, and it is fit for human consumption in accordance to the current Good Manufacturing Practices (GMP) by the FDA.

2. That the product was made in accordance to management’s conformity with the quality system by AMS and the requirements of the Quality System Assessment Program (QSA), and

3. That it complies with the health certifications of the corresponding foreign government (Mexico-SENASICA).

Approved suppliers shall have export products certified as fit for human consumption in accordance to current Good Manufacturing Practices (GMP) by the FDA. In addition to a review of the GMPs, the on-site verification shall also include the importation requirements of the foreign Government.

If you wish to know more about the PEEPEV Program, you may click on the following link: https://www.ams.usda.gov/sites/default/files/media/QAD1062ProcedureProcessedEggsandEggProductsExportVerificationProgram.pdf

If you wish to see the official list of the Program, you may click on the following link for the PEEPEV Program:

If you wish to know more about the PEEPEV Program, you may click on the following link: https://translate.google.com.mx/translate?hl=es-419&sl=en&u=https://www.ams.usda.gov/services/imports-exports/further-processed-egg-products-verification-program&prev=search

Quality System Assessment Program (QSA) approved by the USDA

The QSA Program provides companies supplying agricultural products and services, the opportunity to ensure clients are capable of providing products or services of a constant quality. To operate a QSA Program, a company shall develop and submit a documented plan complying with the requirements of the program. The scope of the on-site verification process shall be directly related to the complexity of the certification statements for the product required by the destination foreign Country. The competent auditors of the Livestock and Poultry Program are responsible for reviewing and approving the companies as eligible suppliers under the Processed Egg and Egg Products Verification Program. Once the suppliers are approved under the Program, they are added to the official list of suppliers.